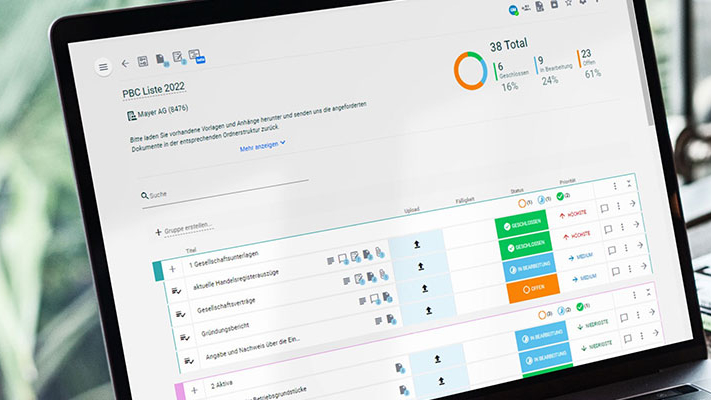

Why companies use the Open Telekom Cloud and what challenges they have solved with it – our customers are best placed to answer that question. Discover a wide range of customer projects in our references. Time and again, the same strengths become evident that make the Open Telekom Cloud stand out: The European cloud meets various data protection requirements, from GDPR compliance to the protection of professional secrecy. It offers personalized service and support, assisting customers at every stage of their cloud journey. The data centers are operated sustainably and contribute to individual climate targets. These are all strengths that independent market analysts repeatedly highlight. The result is a powerful, secure, and reliable cloud that is suitable for a wide range of industries and use cases.

The Open Telekom Cloud Community

This is where users, developers and product owners meet to help each other, share knowledge and discuss.

Free expert hotline

Our certified cloud experts provide you with personal service free of charge.

0800 3304477 (from Germany)

+800 33044770 (from abroad)

24 hours a day, seven days a week

Write an E-Mail

Our customer service is available free of charge via E-Mail

AIssistant Cloudia

Our AI-powered search helps with your cloud needs.